We are discussing about structural erection of 660 MW boiler and its sequence . Therefore it is

felt prudent to provide some more data we found relevant for the topic.

- Size of ceiling girders we used for the plant.

-Pre-assembly welding etc were discussed earlier. But this will give an idea about weight to be

lifted from ground to top of the 7th tier column.

- We will give the approximately time taken to accomplish the task in a sequential manner.

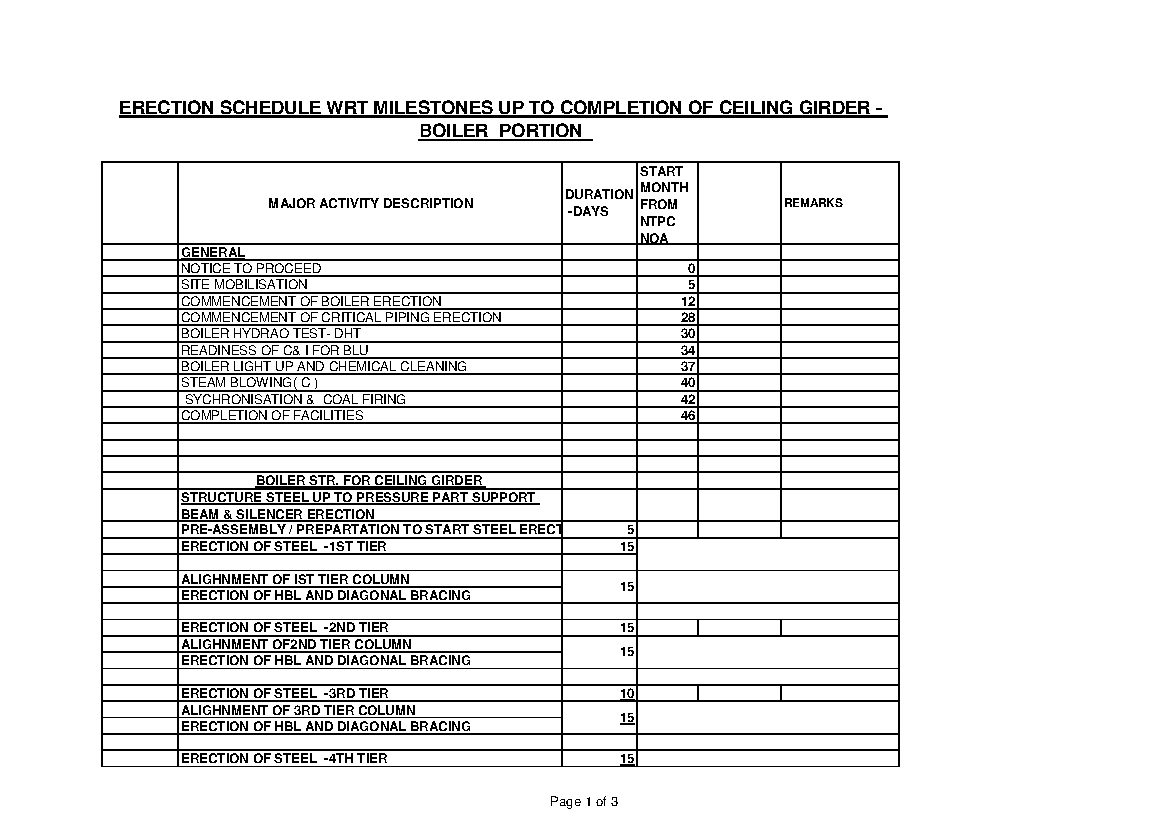

We have given an erection program suits to Indian manufacturer. It seen that around 120 days to

140 days are the cycle time up to 7th tier erection of column and readiness of C.G lifting. Total

Cycle of CG lifting is around 75 days including erection of WB , RB , S17 column and associated

Bracing ( Horizontal and Diagonal). Girder erection should start around 110 days after the first

column erection. It should move sequentially by completing one by one girder.

- Platform and members of MBL ( small members ) erection to start after one month of Erection

start.

- Once we complete all the ceiling Girders we start erecting central columns and its members

so that we will be ready for pressure parts erection.

- Also we start the erection Air Heaters columns on the rear side and getting ready for Air

heater erection. This structural erection with all platforms will take two months from the

starting of first Air heater column.

- Before start of erection column the area is being used for feed material into the cavity. Once

we start erecting Air heater column then approach should be opened between two foundations

of FD Fan.

- It is preferable to erect ECO handling structure in this juncture other wise there will be approach

problem for top tier erection with heavy duty crane .

-Beside boiler structure one independent area for structural work is between ESP outlet to Chimney

inlet flange . Inside chimney up to nearly 34 M height. This area should be started as early as

possible because lot of structural work is there and it will open the front for ducting.

- Boiler Outlet flange to ESP inlet structural work starting depends on completion of Air

heater heavy lifting , Boiler outlet flange lifting , Erection of FD fan silencer , ECO

handling structure erection and erection of ESP inlet flange. This is very critical area

because it has interface with CHP and coal conveyor gallery , LP piping , Cabling etc.

- Following electrodes are used for structural erection.

a. E6013 - Rutile electrodes for mild steel and low carbon steel.

b. E6027 - Rutile electrodes for deep penetration and high deposition.

c. E7016 - Low hydrogen Electrodes for thick section structural steel.

Depends on applications these electrodes are used . There are many companies in INDIA

who are manufacturing the same .

from next submission we will discuss about Pressure part erection.

Sir we are Armstech erectors & Engineers Pvt Ltd(Sub contractors) doing powerplant erection.If any power plant related jobs.Please contact

ReplyDelete09745222033

For all upcoming Structural work Government and Private Sector Tenders in india do visit TenderMines.com

ReplyDeleteThis comment has been removed by the author.

ReplyDelete