Seal air fans are located at zero metre level between first pass and second pass. These are high

speed fans and prone to high vibration and risk. Therefore it needs special care to commission

these fans. All individual items to be checked during assembly and protocoled that includes brg

lubrication for DE ,NDE of motor and fans and other c&i items.

suction Duct.

to individual mills are opened keeping the dampers of other mills in closed condition.

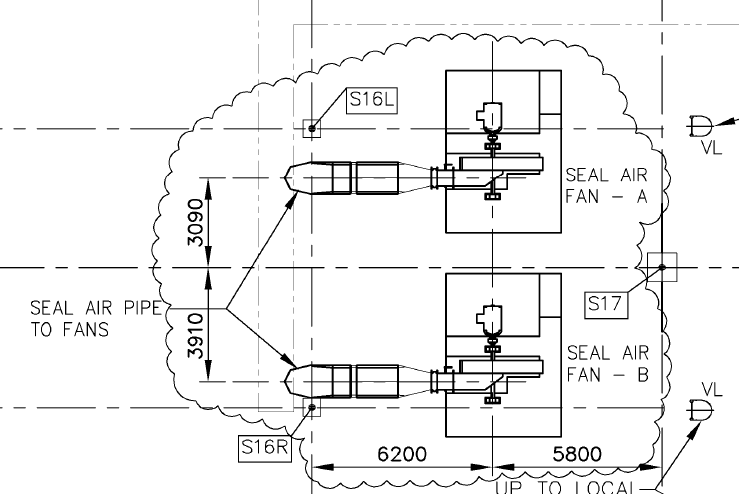

The drawing shows the location of seal air fan at Boiler and its ducting and piping.

P.S If you are looking to earn few legitimate extra money from the comfort of your home then please click on the link given below

LINK 1 - PLEASE CLICK HERE

LINK 2 - PLEASE CLICK HERE

speed fans and prone to high vibration and risk. Therefore it needs special care to commission

these fans. All individual items to be checked during assembly and protocoled that includes brg

lubrication for DE ,NDE of motor and fans and other c&i items.

The Seal air fan system consists

of the following items.

Cold Primary air Suction duct.

2 Nos of filter & its associated dampers &

bleed air lines.

2 Nos. fan with motor.

Suction Dampers of Seal Air Fan

Discharge Dampers of Seal Air Fan

Discharge Ducts up to Mill Seal air points

Seal Air Fan basically functions as booster fan taking

suction from primary air fan discharge (cold

primary air before AH-A&B)

boosting up the air pressure and supplying seal air to various sealing

points of Bowl Mills.

Seal Air Fan Suction Pressure : 580 mmwc ( for 500 MW units only)

Seal Air Fan Discharge Pressure : 1088

mmwc ( ----do)

Filters are provided in the Suction line of the Seal air fan

with a provision to continuously bleed any

dusty air in to furnace through

Secondary air duct-wind box.(WB)

Objective to

Commission Seal Air Fan and make it available for Bowl Mill Commissioning.

The Commissioning of Seal Air Fans and its system is carried

out as follows:

a. Cleaning

of Suction Duct through filter up to fan

suction point.

b. Trial run

of fans & cleaning of discharge ducts up to Mill Seal Air input points.

SAFETY PRECAUTIONS:

Debris in and around Fan and Duct area to be removed.

Approach / Stair Case / Platform where ever required are

made available.

The Test team should know well about the procedure to be

adopted in case of damage to machinery

or injury to personnel connected to the

activity.

The Commissioining team should be well aware of procedures

to be adopted in case of any

abnormality.

STATE OF THE PLANT:

The Seal Air Fan and its associated duct system are erected

as per recommended drawing.

Filter erected with its bleed line to WB.

Power Supply system for the fans are commissioned and

available for operation.

Required Local / Remote I & C Inputs are made available .

Inlet and outlet dampers of fan and damper erected and are freely operating.

Small duct piece at Suction of the Seal Air Fan removed for

cleaning the Suction duct or Suitable

opening to be made at suction header of

the fan for cleaning the fan suction duct.

All the hoses connected the Mill Sealing locations are kept

removed for discharge duct cleaning / Fan

trial run.

Suction / Discharge ducts support completed as per drawing.

PA Fans and primary System available for operation from control

Room.

Required local / Remote C & I inputs are available (list

to be prepared at site)

Primary air inlet / outlet dampers of Primary APH are kept

at suitably modulated position for this

cleaning activity.

System made ready :

PA Fan (A/B) cold Primary air before APH –

filter ( A/B) – Seal Air Fan suction Duct.

Start any one of the PA fan and gradually load the fan to

reach discharge pressure of about 500

mmwc.

Sufficiently blow the duct from cold primary Air before APH

take-off point to Seal Air Fan suction.

Air blowing to be continued till clean air observed at Seal

Air fan suction point.

(Duration : About 15

mts)

Parallel, open the valve in the bleed line of Filters one by

one and blow the bleed line into WB.

(Duration : about 10 mts)

Release the system for Seal Air Fan Trial run / cleaning of

Seal Air Fan discharge System.

System made ready: PA Fan (A/B) discharge duct with one man

hole door opened – Filters – Seal Air

Fan suction duct – Seal Air Fan –

Discharge duct up to mill Sealing location. (PA Fans in switched

off

condition).

Keeping the suction damper in open and discharge damper in

close condition, start one Seal Air Fan,

Keeping the other fan in isolated

condition.

Open the discharge damper slowly and ensure that the Seal

lines to the Mills are blown.

Put the Seal air Fan under 8 Hrs trial run and during this

period, measure Fan load current and

vibrations and other parameters for

records.

Cleaning of all Seal lines to mills are done one by one or

by pair and for this, the main inlet damper to individual mills are opened keeping the dampers of other mills in closed condition.

Once or twice, the Seal air lines to Mills are gently tapped

to dislodge all the loose particles from the

piping.

Stand by Seal air fan also put on 8 Hrs trial run as

explained above.

At the end of 8 Hrs trial run, the Seal air

lines to Mills are normalisedThe drawing shows the location of seal air fan at Boiler and its ducting and piping.

P.S If you are looking to earn few legitimate extra money from the comfort of your home then please click on the link given below

LINK 1 - PLEASE CLICK HERE

LINK 2 - PLEASE CLICK HERE