Till

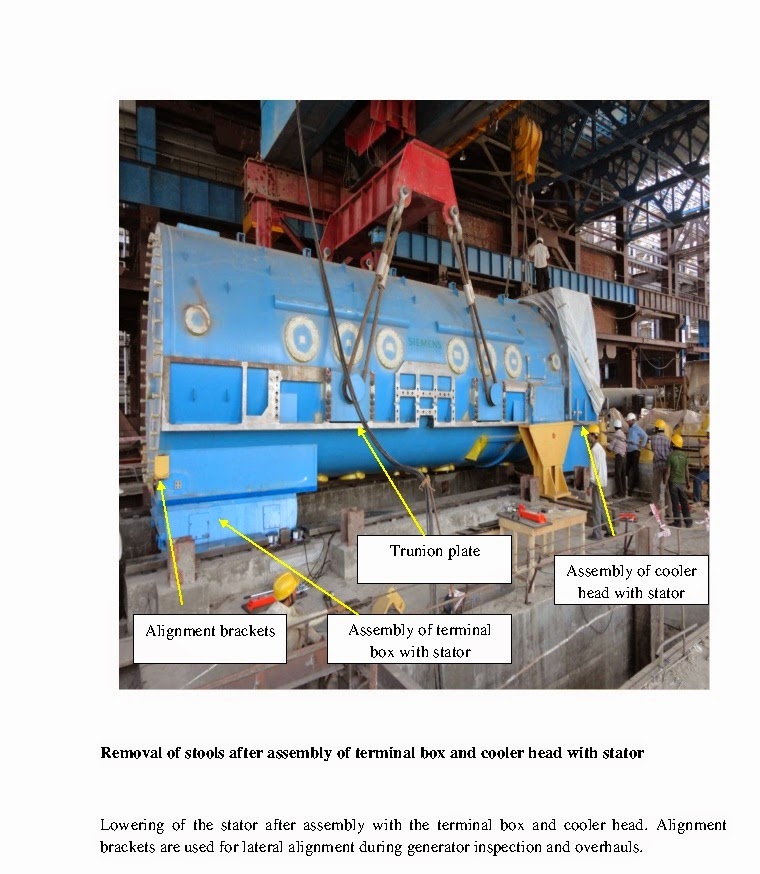

last dispatch I have outlined the installation of turbine and generator

of thermal power plant briefly with the help of photos. I have also discussed

what are pitfalls during erection . From now onwards I will discuss about few

important systems /processes required for Turbine and Generator so that readers

can have an idea of the total system of a power plant. I will first discuss

about the Generator System.

Shaft seals supplied with pressurized seal oil

are provided to prevent hydrogen losses at the shaft and the ingress of air into the hydrogen-cooled

generator. All generators having rating more than 500 MW stator winding is

cooled by water and rotor winding is cooled by Hydrogen. Stator water and

Hydrogen is again cooled by water as secondary cooling through stator water

cooler and hydrogen cooler. As long as the seal oil pressure in the annular gap

is more than the gas pressure in the generator, no hydrogen will escape from

the generator housing. During normal operation, the air side seal oil pump (AC)

draws the seal oil from the seal oil storage tank and feeds it to the shaft

seals via coolers and filters. The seal oil supplied to the shaft seals which

drains towards the air side through the annular gaps between the shaft and seal

rings is returned to the seal oil storage tank. For the air side seal oil

circuit, three seal oil pumps are provided with one of the three pumps always

in operation. In the event of a failure of the pump in service due to a

mechanical or electrical failure, the second pump automatically takes over. If

both pumps fail, the seal oil supply is taken over by the stand-by pump without

any interruption.

During normal operation, the hydrogen side pump draws the seal oil from the seal oil storage tank

and feeds it to the shaft seal via coolers and filters. The seal oil supplied to the shaft seals which

drains towards the hydrogen side through the annular gaps between the shaft and the seal rings is first collected in the generator pre-chambers and then returned to the seal oil tank.

Oil pressures which exceed the

generator gas pressure are required to ensure proper sealing of the generator.

With the seal oil pumps in operation, the seal oil pressure is controlled by differential

pressure valves. The first valve controls the seal oil pressure after two

equal-priority ac air side seal oil pumps. The pressure after the stand-by seal

oil pump is separately controlled by the second valve. Depending on the valve

setting and the impulse oil pressure prevailing (seal oil pressure and hydrogen

casing pressure), a larger or smaller amount of oil is returned to the suction

pipe so that the required seal oil pressures is established at the shaft seals

. A typical seal oil circuit is given below. Now seal oil system is coming as a

skid item where every item is connected ,pre-wired and instrumentation

completed. Only job is left to connect the lines from different places with

proper slope. However only small disadvantage is there i.e. the size of the

skid is fairly big because of cooler and tank fitted on it. If proper

co-ordination is not done there will be problem on shifting the same to

foundation in one piece. One must keep in mind pre-plan its path before hand.

typical seal oil system P&ID diagram of BHEL supplied 5000MW set.

P.S If you are looking to earn few extra money from the comfort of your home then please click on the link given below

LINK 1 - PLEASE CLICK HERE

LINK 2 - PLEASE CLICK HERE

P.S If you are looking to earn few extra money from the comfort of your home then please click on the link given below

LINK 1 - PLEASE CLICK HERE

LINK 2 - PLEASE CLICK HERE